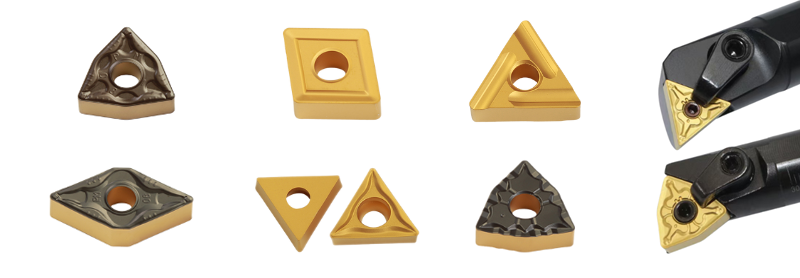

End Mill Cutting Tools Made From Quality Carbide

We have a wide selection of cutting tools which includes top - notch carbide end mills which we sell in Shandong Zhongren International Trade Co., Ltd. Their excellent construction makes them able to withstand wear, carve grooves/slices, and milling complex shapes making them useful in diverse emerging fields like automotives, aerospace, and mold - making industry, or in other places requiring heavy-duty equipment. Custom made tools are also available and you can find more info at shandongyunfeishukong.com.

Get A Quote