Jinan City, Shandong Province, China. [email protected]

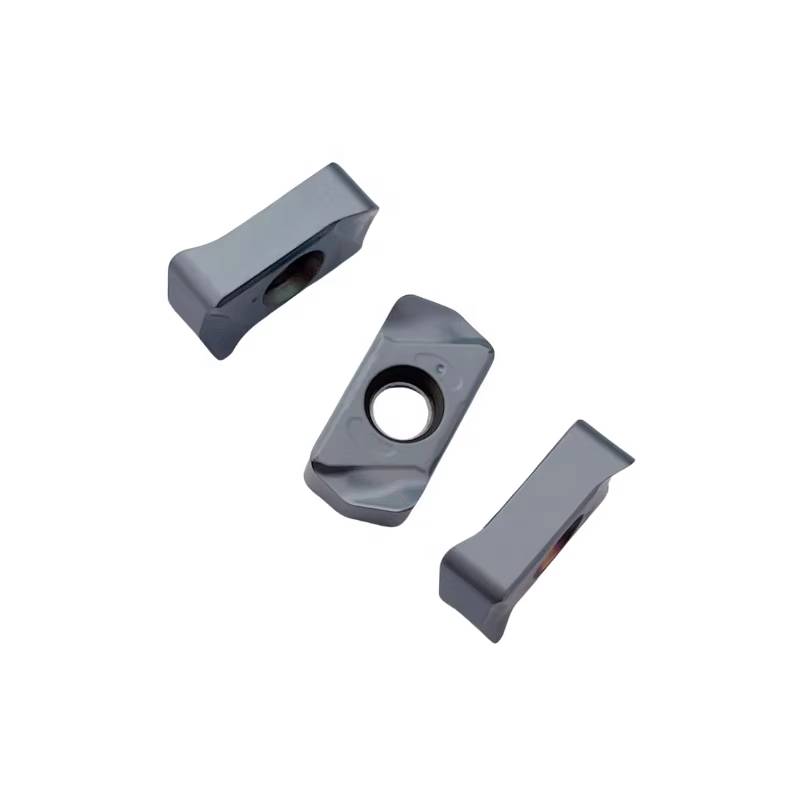

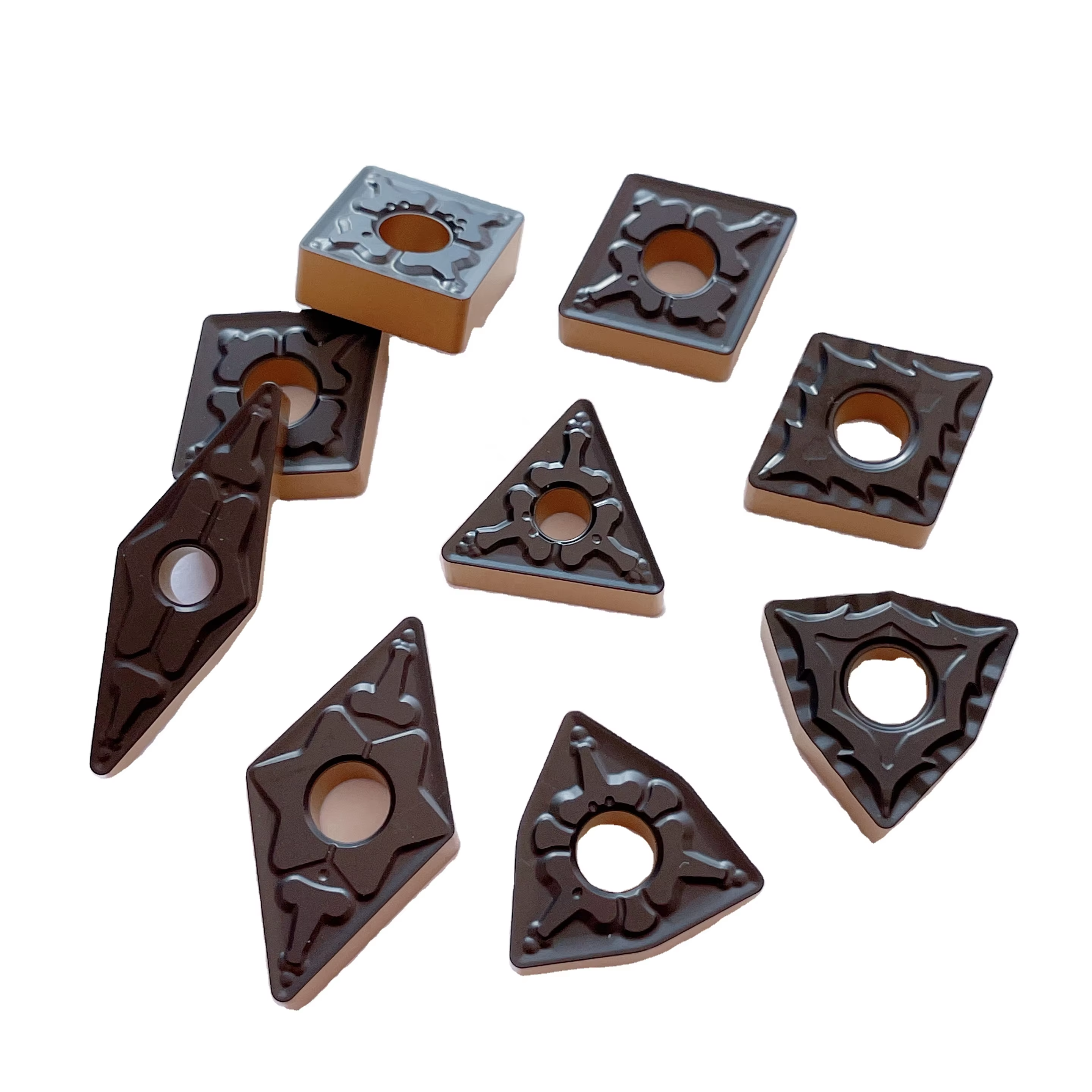

When it comes to carbide turning tools, Shandong Zhongren International Trade Co., Ltd. is the name that stands out in the industrial manufacturing landscape. Carbide turning tools are essential for achieving high - precision turning operations on various metals. Our carbide turning tools are made from high - quality carbide materials, which offer exceptional hardness and wear resistance. This allows them to maintain sharp cutting edges for extended periods, even under high - speed and high - load conditions. The precise design of our carbide turning tools ensures optimal chip control, reducing the risk of chip - related issues such as chip jamming and surface damage. We offer a wide range of carbide turning tools, including different nose radii, cutting edge angles, and shank types, to suit different turning applications and machine configurations. Our R & D team is constantly working on improving the performance of our carbide turning tools by exploring new carbide grades and tool geometries. With our carbide turning tools, manufacturers can achieve higher productivity, better surface quality, and tighter tolerances, giving them a competitive edge in the global market.