Jinan City, Shandong Province, China. [email protected]

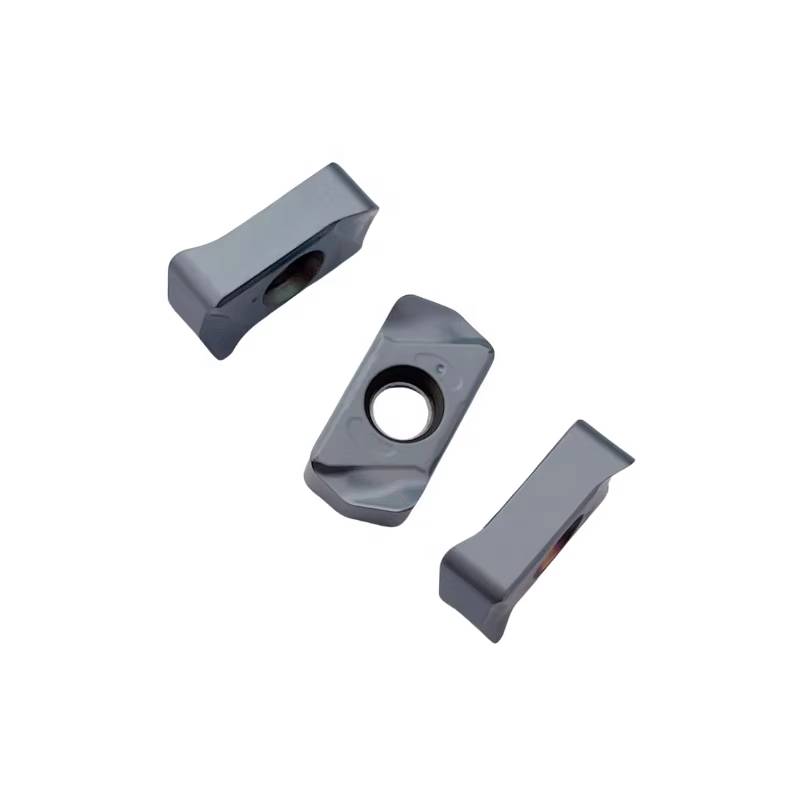

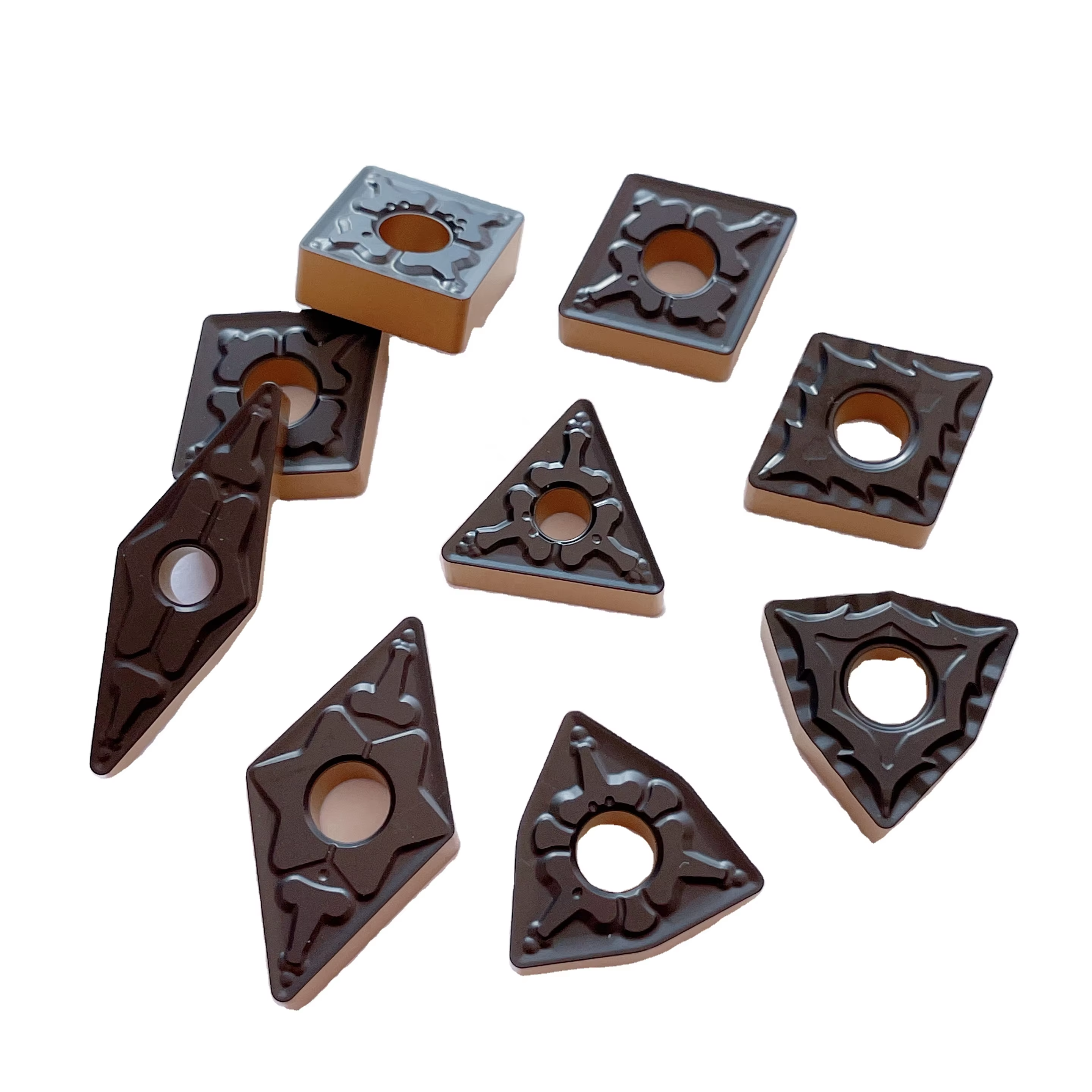

Experience Unmatched Slotting Performance with Shandong Zhongren International Trade Co., Ltd.'s Slotting Carbide Tools. Slotting operations are critical in many manufacturing processes, requiring tools that can deliver precise and efficient cuts. Our slotting carbide tools are engineered to meet these demands, featuring a high-grade carbide construction that ensures exceptional hardness and wear resistance. The precise geometry of our tools optimizes chip evacuation and minimizes vibration, resulting in cleaner slots and improved surface quality. With a range of options to suit different slotting applications and materials, our slotting carbide tools are the perfect choice for manufacturers seeking to enhance their slotting capabilities and achieve superior results.