Jinan City, Shandong Province, China. [email protected]

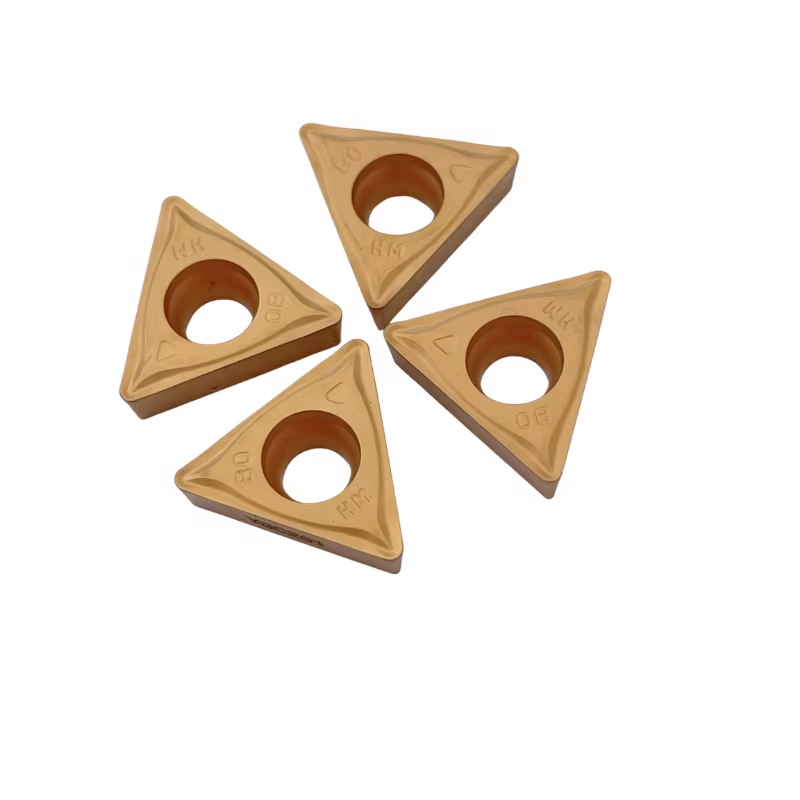

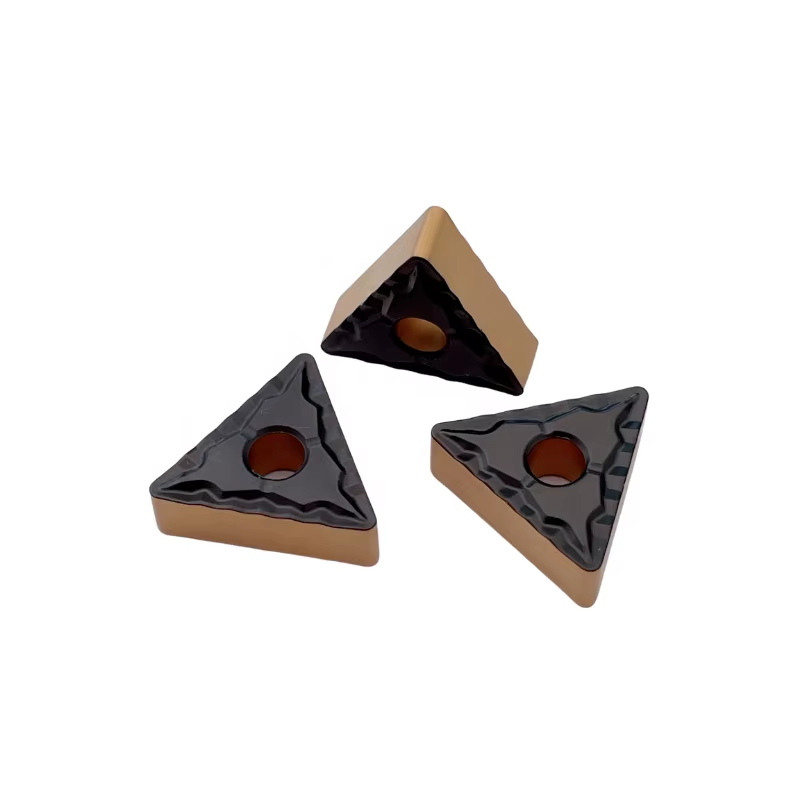

Our collection of milling cutting tools features tools every machining shop needs. These tools are multi - functional and can be used for a number of milling operations. In the aerospace sector, they assist in the accurate machining of highly intricate components. For mold making, these tools serve the purpose of machining elaborate mold cavity depressions. We use advanced manufacturing techniques to ensure the quality of our tools. If you require a certain style of a milling cutting tool, we are more than happy to customize it for you. Check out our website to browse our extensive collection of milling cutting tools.