Jinan City, Shandong Province, China. [email protected]

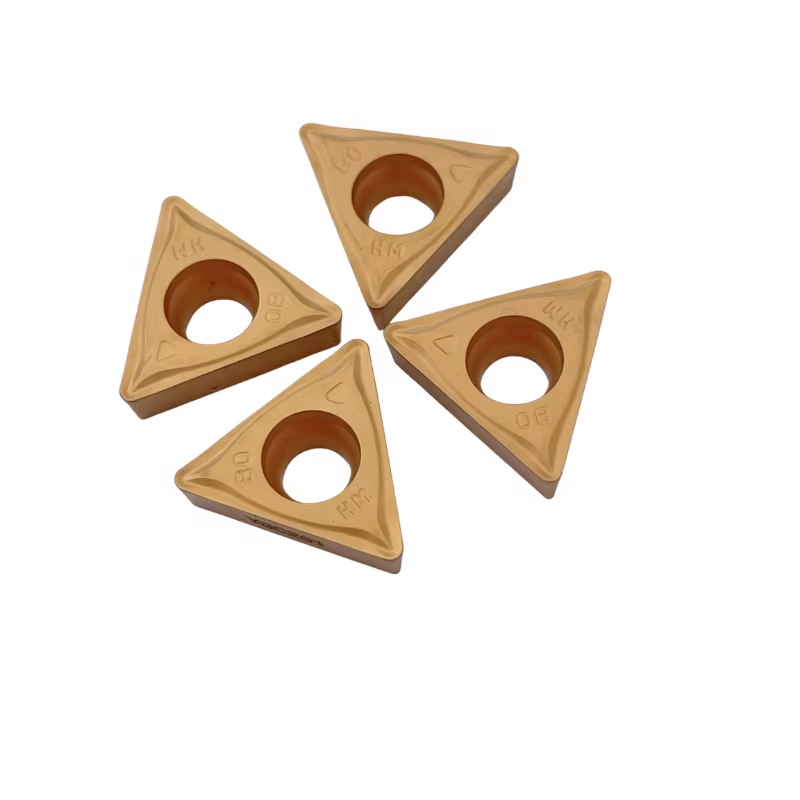

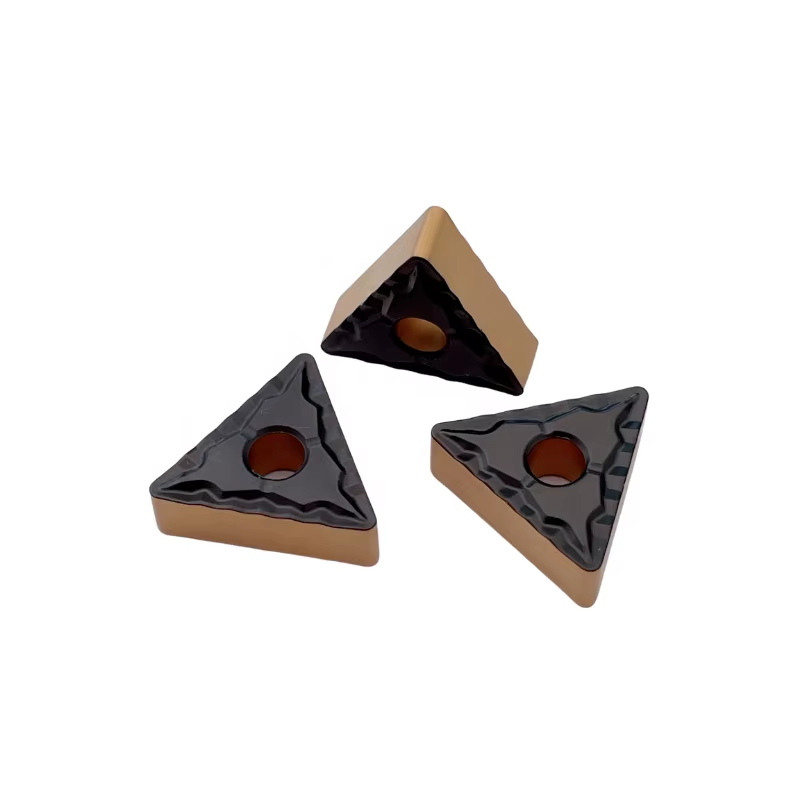

We have developed turning cutting tools for maximum efficiency and accuracy. Striving to achieve precision in high-precision components ranging from small automotive parts to large rail parts? Our tools can effortlessly manage any turning tasks. Their long lifespan can be attributed to their construction from top-grade materials. Acknowledging that each turning job comes with its own set challenges and requirements, we provide customization options. Supporting consulting services are available to assist in selecting the most appropriate turning cutting tool. To look for the right tools, check our website.