Jinan City, Shandong Province, China. [email protected]

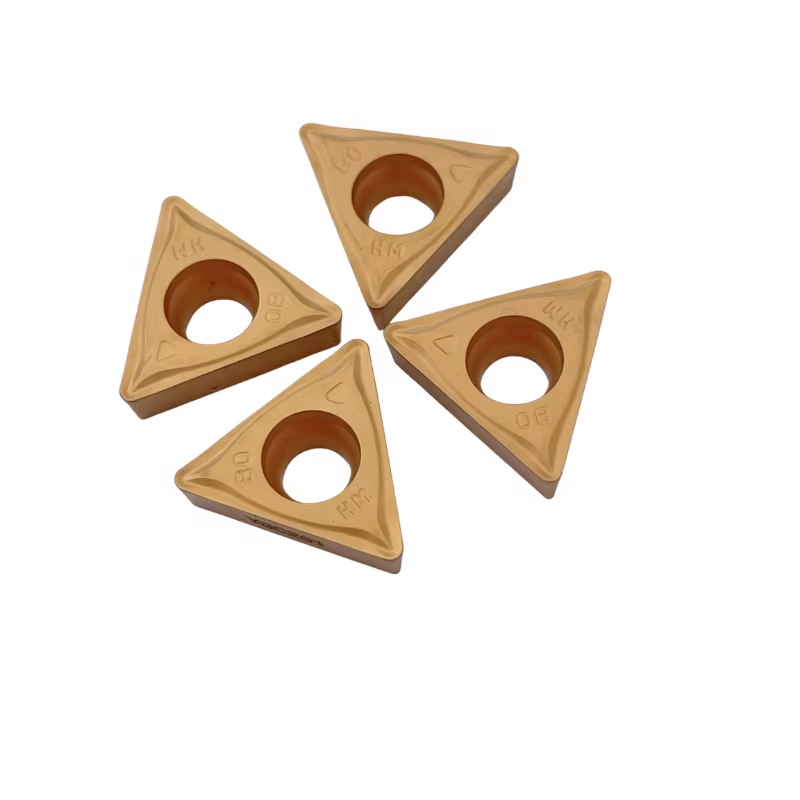

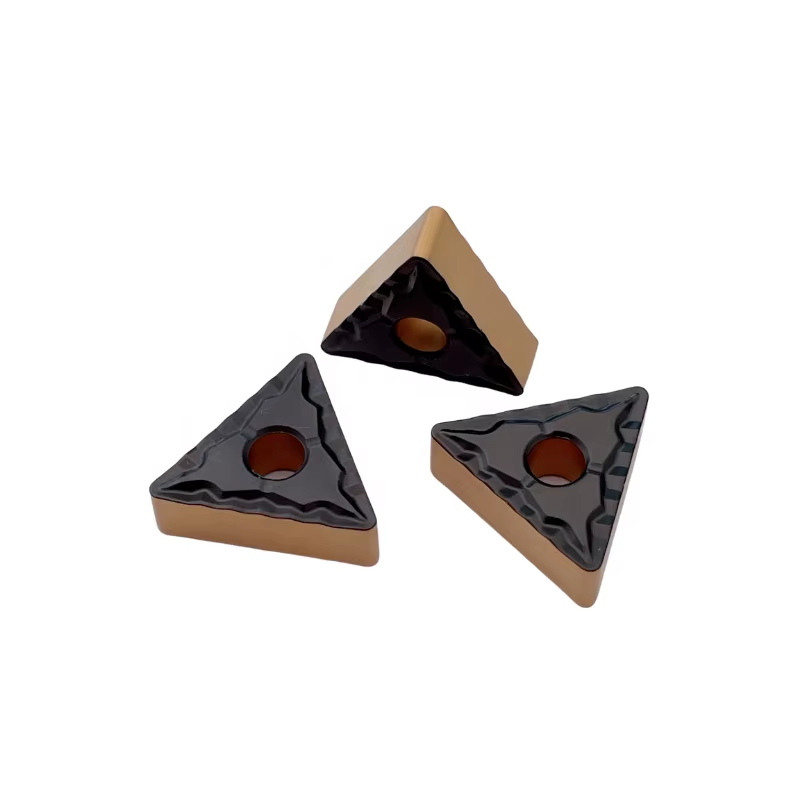

Shandong Zhongren International Trade Co., Ltd. is a leading manufacturer of high - performance carbide cutting tools. In the industrial manufacturing sector, carbide cutting tools are widely recognized for their superior performance in metal processing. Our carbide cutting tools are made from high - grade carbide materials, which are composed of tungsten carbide particles bonded together with a metallic binder. This combination gives our tools exceptional hardness, wear resistance, and heat resistance, making them ideal for high - speed and high - precision machining operations. We offer a comprehensive range of carbide cutting tools, including turning tools, milling tools, drilling tools, and threading tools. Each type of tool is designed with precision to meet specific machining requirements. Our carbide turning tools are available in different geometries and nose radii, suitable for rough and finish turning of various metal materials. Our carbide milling tools come in a variety of flute counts and helix angles, enabling efficient material removal and smooth surface finishes in milling operations. Our carbide drilling tools offer excellent hole quality, with minimal deviation in diameter and roundness. We also provide customized carbide cutting tools to meet the unique needs of our customers, taking into account factors such as the material properties, the machining process, and the production requirements. With our cutting - edge technology, exceptional quality, and customized services, our carbide cutting tools have become a preferred choice for global high - end manufacturing, helping our clients achieve higher productivity, lower costs, and better product quality.