Jinan City, Shandong Province, China. [email protected]

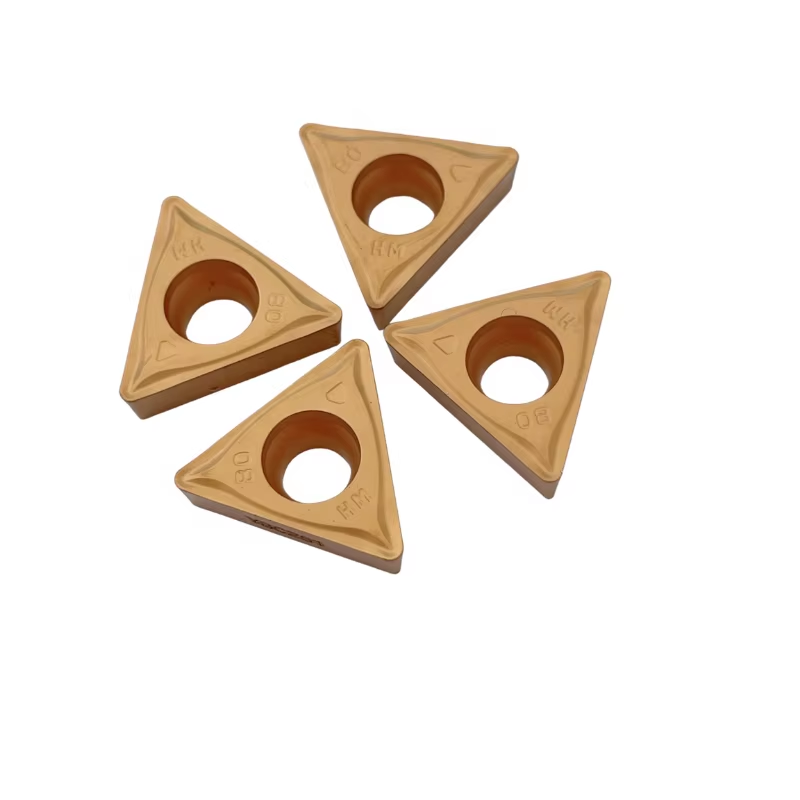

Precision Manufacturing, Driving the Future: Shandong Zhongren International Trade Co., Ltd. stands as a paragon in the realm of CNC lathe tools. As a professional CNC cutting tool factory, we recognize that CNC lathe tools are the linchpin in the metal - processing chain, enabling precise and efficient turning operations. Our CNC lathe tools are crafted with cutting - edge technology, integrating advanced materials and innovative designs. The high - precision manufacturing process ensures that each tool meets the most stringent tolerances, guaranteeing consistent performance in every machining task. Whether it's for rough turning to remove large amounts of material quickly or fine turning for achieving ultra - smooth surface finishes, our CNC lathe tools excel. We offer a comprehensive range of tools, including different geometries and coatings, to cater to diverse materials and machining requirements. Our dedicated R & D team continuously explores new possibilities, pushing the boundaries of what CNC lathe tools can achieve. With exceptional quality control measures in place, we ensure that every tool leaving our factory is of the highest standard, providing our global customers with reliable and long - lasting solutions for their high - end manufacturing needs.