Jinan City, Shandong Province, China. [email protected]

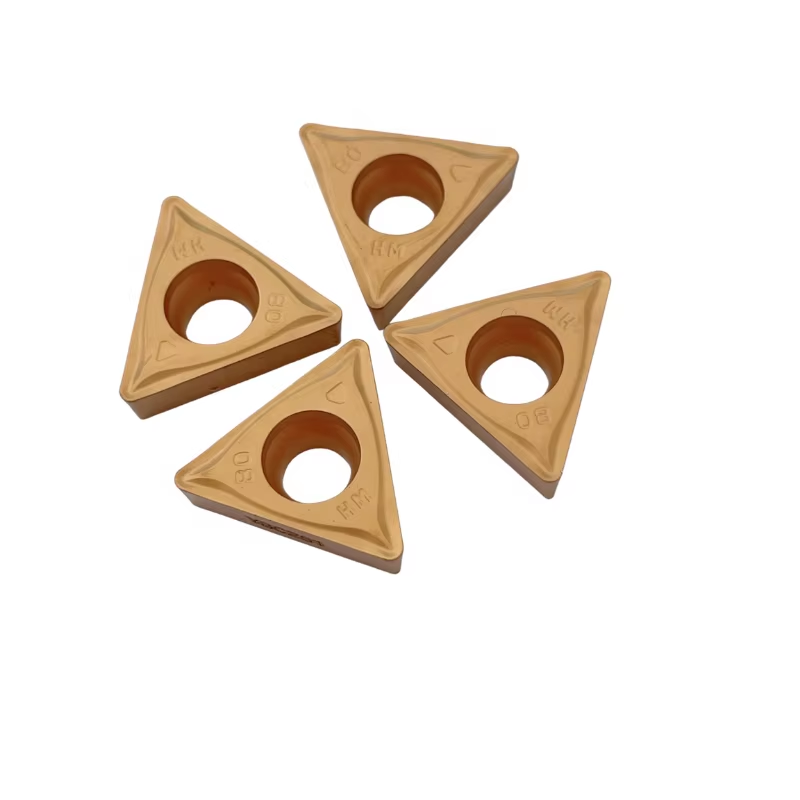

Looking for performance-focused CNC milling tools? If conquering challenges is your strength, our performance focused tools will satisfy your needs. These tools are indispensable in the aerospace sector for the production of advanced parts and are essential in the moldsmithing realm for the creation of perfect contours and geometries. We boast an extensive selection of tools which can be tailored to suit your exact requirements. Get in touch with us for additional details about our CNC tools for milling and check out our site.