Jinan City, Shandong Province, China. [email protected]

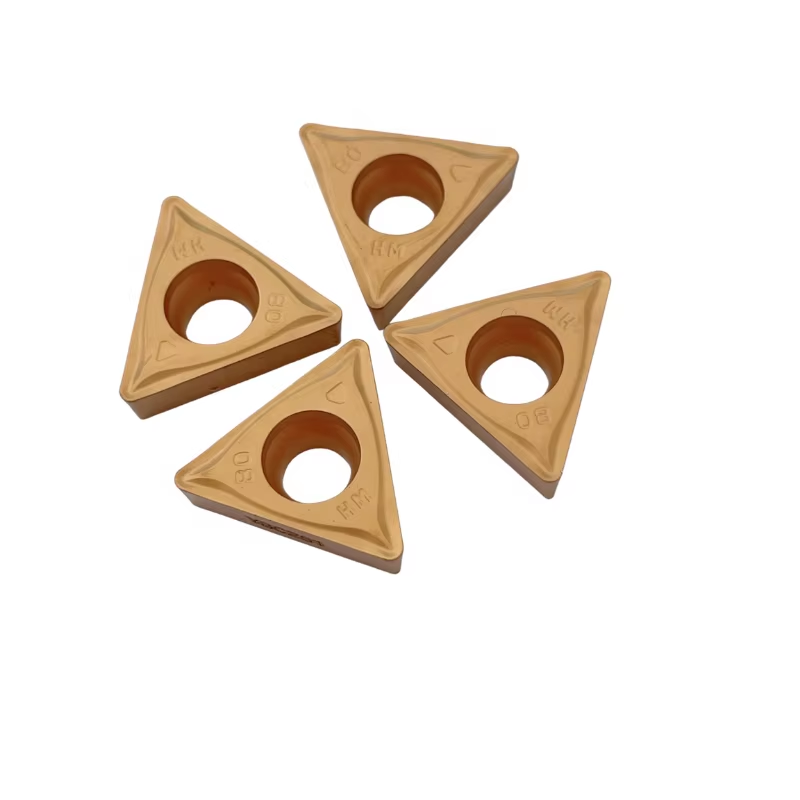

Shandong Zhongren International Trade Co., Ltd. offers a comprehensive range of CNC tool holders that are designed to securely hold and position cutting tools during machining operations. These tool holders are made from high-quality materials, ensuring rigidity and stability, which are crucial for achieving precise and accurate machining results. The company's CNC tool holders are compatible with various types of cutting tools, including carbide inserts, and are suitable for use in different CNC machine tools. They feature easy installation and adjustment, allowing for quick tool changes and minimizing downtime. With advanced design and manufacturing processes, the CNC tool holders provide excellent vibration damping capabilities, reducing tool wear and improving the surface finish of the workpiece. The company's commitment to quality ensures that its CNC tool holders meet the highest industry standards.