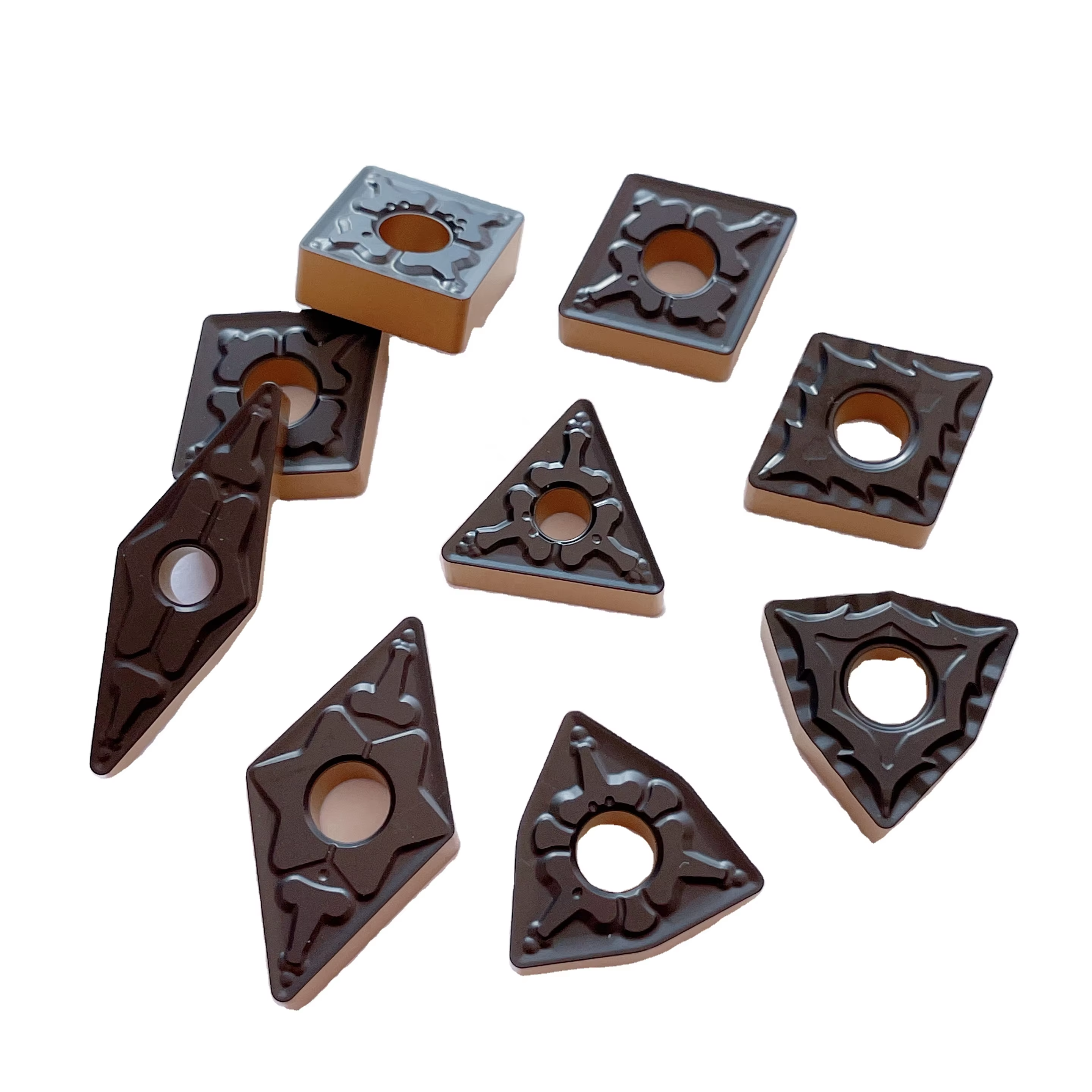

Dependable Machining Operational After – Sales Support – Softens Sales Transactions

Every customer require not only top quality products but also first class support services. Choose the tungsten carbide tools from Shandong Zhongren and rest assured knowing you are receiving different grades of service; pre-purchase consultations, SAT and SAT+ services as well as continual technical support throughout the entire lifetime of the sold product. Our trained and fully competent support personnel are at your service to address tool application problems and resolve any issues you might have at any time of the day or night. We perform scheduled and unscheduled maintenance services without any cost exposure to you for servicing your tools that developed faults because of manufacturing inadequacies. Consequently, all your values of machining operations will be achieved; they include total process automation, zero downtime, and 100% operational productivity.