Jinan City, Shandong Province, China. [email protected]

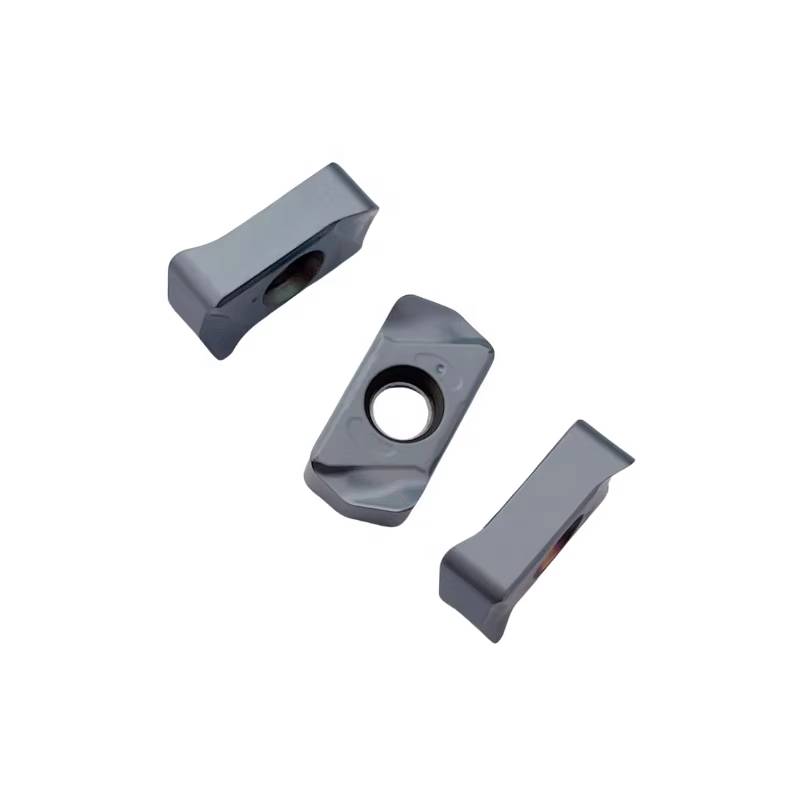

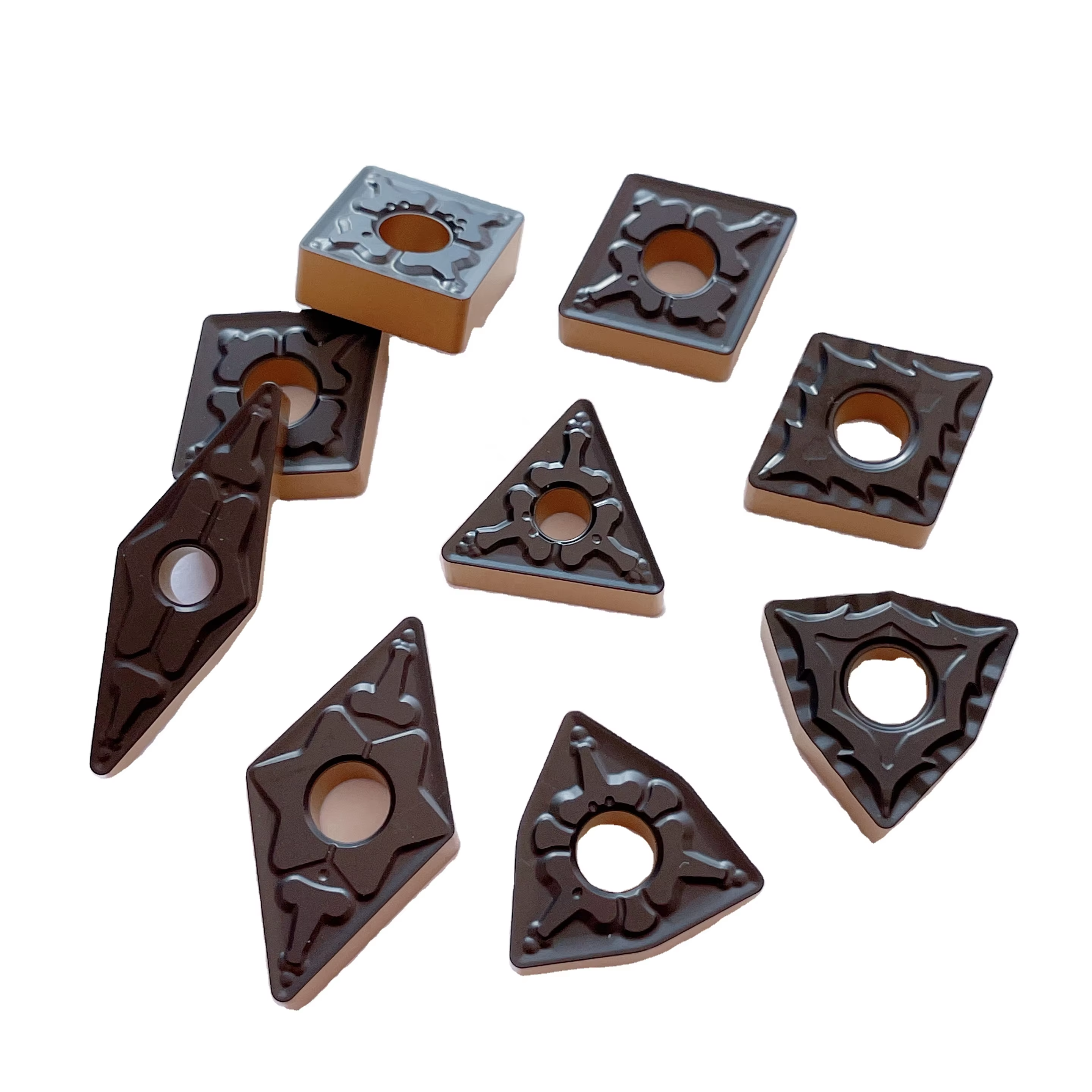

Elevate Your Machining Capabilities with Shandong Zhongren International Trade Co., Ltd.'s Premium CNC Carbide Tools. In the competitive landscape of industrial manufacturing, the choice of cutting tools can make all the difference. Shandong Zhongren stands out as a beacon of innovation and quality, offering a wide array of CNC carbide tools that redefine efficiency and performance. Our carbide tools are crafted from the finest carbide materials, known for their exceptional hardness and wear resistance, making them ideal for high-speed and high-precision machining applications. Whether it's milling, drilling, or turning, our CNC carbide tools deliver consistent results, reducing downtime and enhancing productivity. With a focus on continuous improvement, we ensure that our tools meet the evolving demands of modern manufacturing, providing our customers with a competitive edge in the global market.