Jinan City, Shandong Province, China. [email protected]

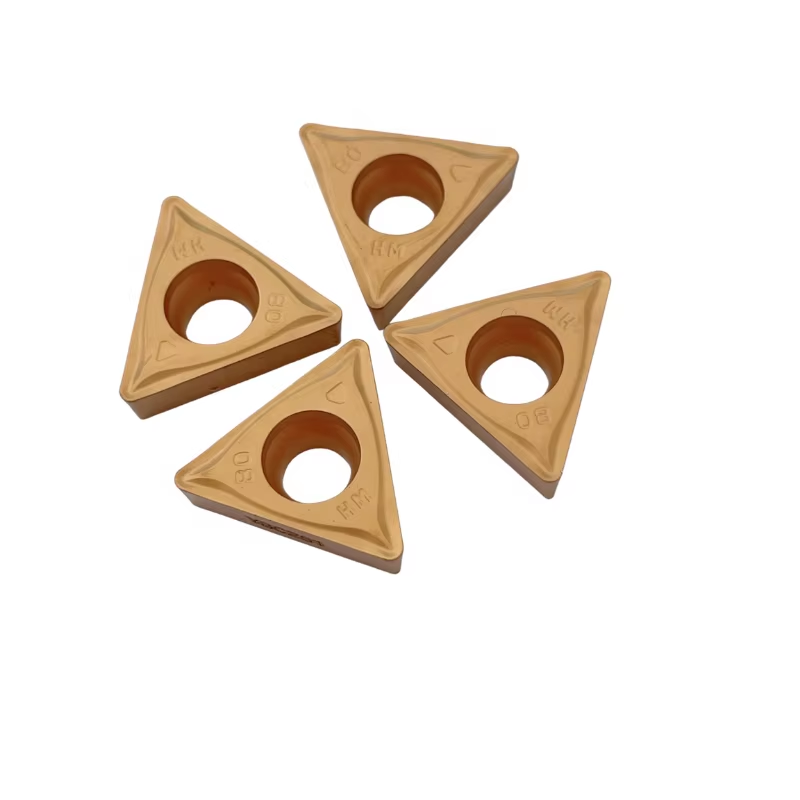

In the dynamic world of industrial manufacturing, Shandong Zhongren International Trade Co., Ltd. is at the forefront with its top - notch CNC tool inserts. CNC tool inserts are the replaceable cutting edges of CNC tools, and their quality directly impacts the overall machining performance. Our CNC tool inserts are made from premium materials, such as high - grade carbide and ceramic, which offer superior hardness, wear resistance, and heat resistance. This enables them to withstand the extreme conditions encountered during high - speed machining, ensuring long tool life and reduced downtime. The precise geometry of our CNC tool inserts is designed to optimize chip formation and evacuation, minimizing the risk of chip clogging and improving surface quality. We also offer a variety of coatings, such as PVD and CVD coatings, which further enhance the performance of the inserts by reducing friction and increasing resistance to chemical wear. Our customized services allow us to tailor the CNC tool inserts to the specific needs of our customers, whether it's for a particular material, machining process, or production volume. With our CNC tool inserts, manufacturers can achieve higher productivity, lower costs, and better product quality.